The solutions described in this case study were provided by Coyote Logistics prior to their acquisition by RXO, Inc., and the teams responsible for designing and executing them are now part of RXO.

Shipper Challenge:

To properly stage a series of warehouse moves, this national tire distributor needed to move high-volumes of inventory on tight schedules without disrupting their normal supply chain operations.

Their Results:

With the help of carefully selected carriers plus our deep project expertise and on-site support, the tire distributor transferred over 55,000 tires-worth of inventory to seamlessly integrate a new warehouse ahead of schedule.

“The team agreed. Between the on-site support and the driver quality they procured, the project went great.

We improved delays in our loading and unloading procedures, and we were able to implement best practices for projects going forward.”

– Regional Transportation Manager, National Tire Distributor

How We Helped this Automotive Shipper Seamlessly Transfer Warehouses

Special freight projects can be a major pain point for even the most efficient shippers.

Effectively handling volume surges, irregular routes, inventory shuffling, and short timelines — all while maintaining regular shipping operations — is tough.

To reduce the risk of disruption, many savvy shippers turn to 3PL partners for help.

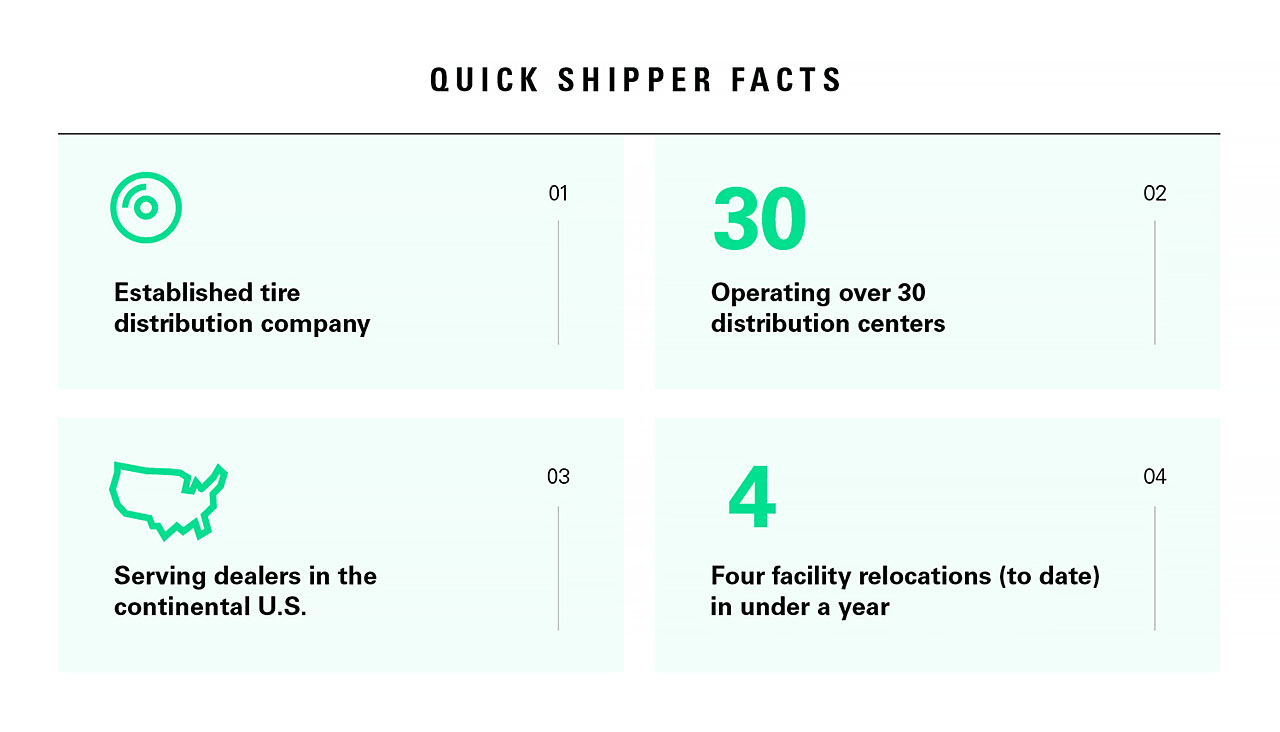

That’s just what this 100-year-old tire distributor did when faced opening a new distribution center in Arizona. The new facility integration would require staging, shipping and stocking of over 55,000 tires, and it would have to happen fast.

Down Time Was Not an Option

As a distributor, their success is dependent on their ability to deliver to their customers; this shipper could not afford a week of supply chain chaos.

In total, they needed to move 270 shipments in four days.

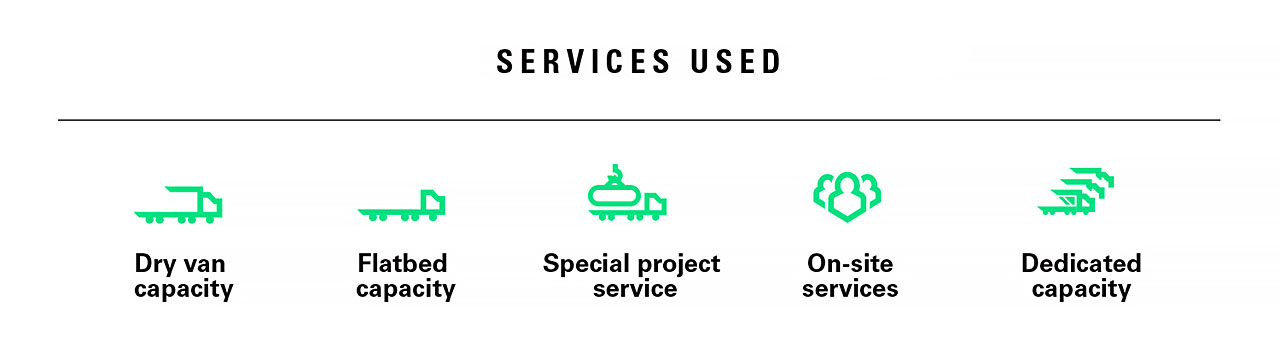

With flexibility and efficiency being a top priority, this national tire distributor knew they needed to partner with a 3PL provider capable of providing superior carrier procurement, detailed tracking and on-site support.

After a comprehensive RFP process, they selected us to help them meet this challenge.

Why this shipper chose us as their 3PL provider for this special project:

- Dense network of reliable regional carriers

- Ability to dedicate carriers to the project

- On-site support from specialized reps

- Comprehensive tracking capabilities

- Deep operational experience in time-sensitive projects

- Unmatched customer service

Using a Dedicated Carriers & a Peak Season-Style Solution

To accomplish this massive facility relocation, we modeled a flexible solution similar to the peak season operations we’ve developed for handling the holiday shipping surge.

What does a dedicated surge solution look like?

- Dedicate a pool of contracted carriers.

- Deploy on-site specialists.

- Work hand-in-hand with the shipper & facilitate driver logistics.

- Assign control teams in the office to oversee the whole project.

Drivers check-in hourly, carriers receive daily performance reviews, and all parties participate in end-of-day debriefs to prepare for the next day of shipping.

Since this model helps us match over thousands of truckloads per day during peak season, we were confident we could develop a similar, yet custom, integrated solution for this shipper.

After three days and 285 truckloads, the new Arizona distribution center was fully stocked. The project was completed 24 hours ahead of schedule due to driver and loading efficiencies.

Not only did this allow the tire distributor to resume regular shipping operations faster, but it saved them from paying for two additional shifts of drivers.

The Transportation Manager at the national tire distributor who oversaw the project commented on our support: “Our team had nothing but positive things to say about their on-site support. They were high energy and did everything necessary to smooth out any potential issue that may have come up to help keep us moving.”